Engineering and consulting

Innovative solutions for every field of application

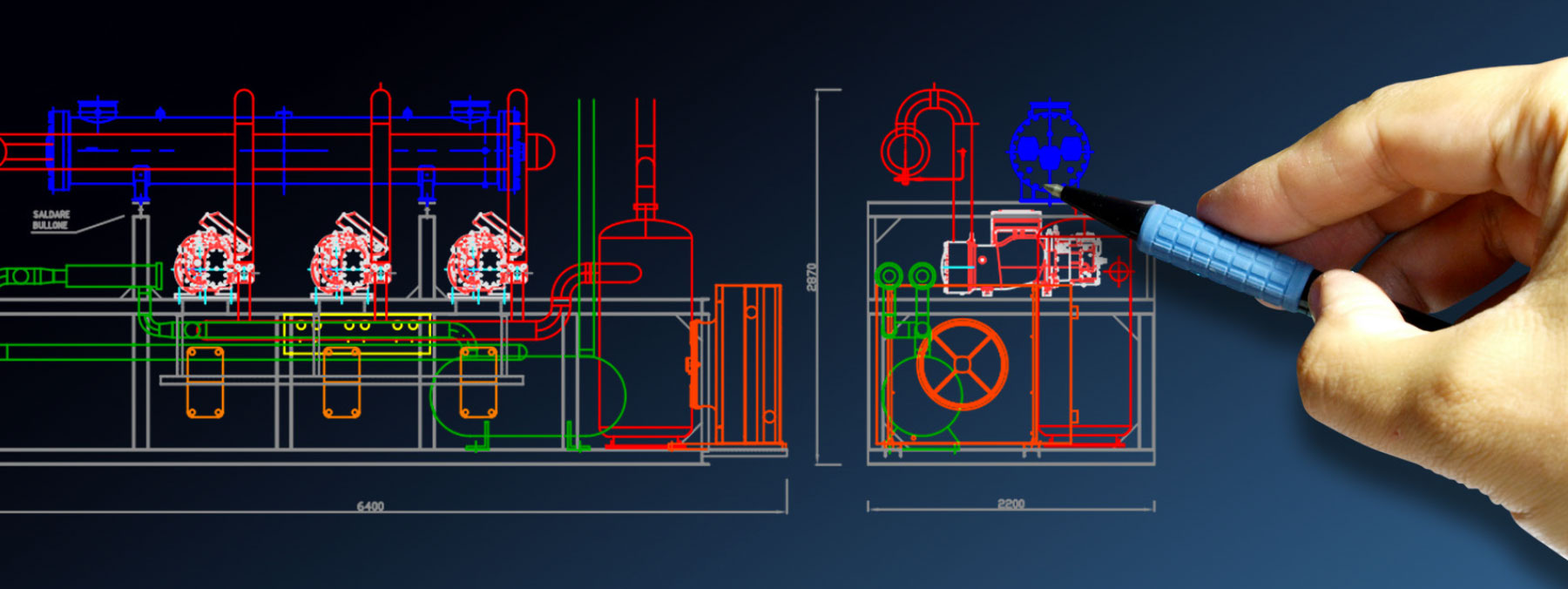

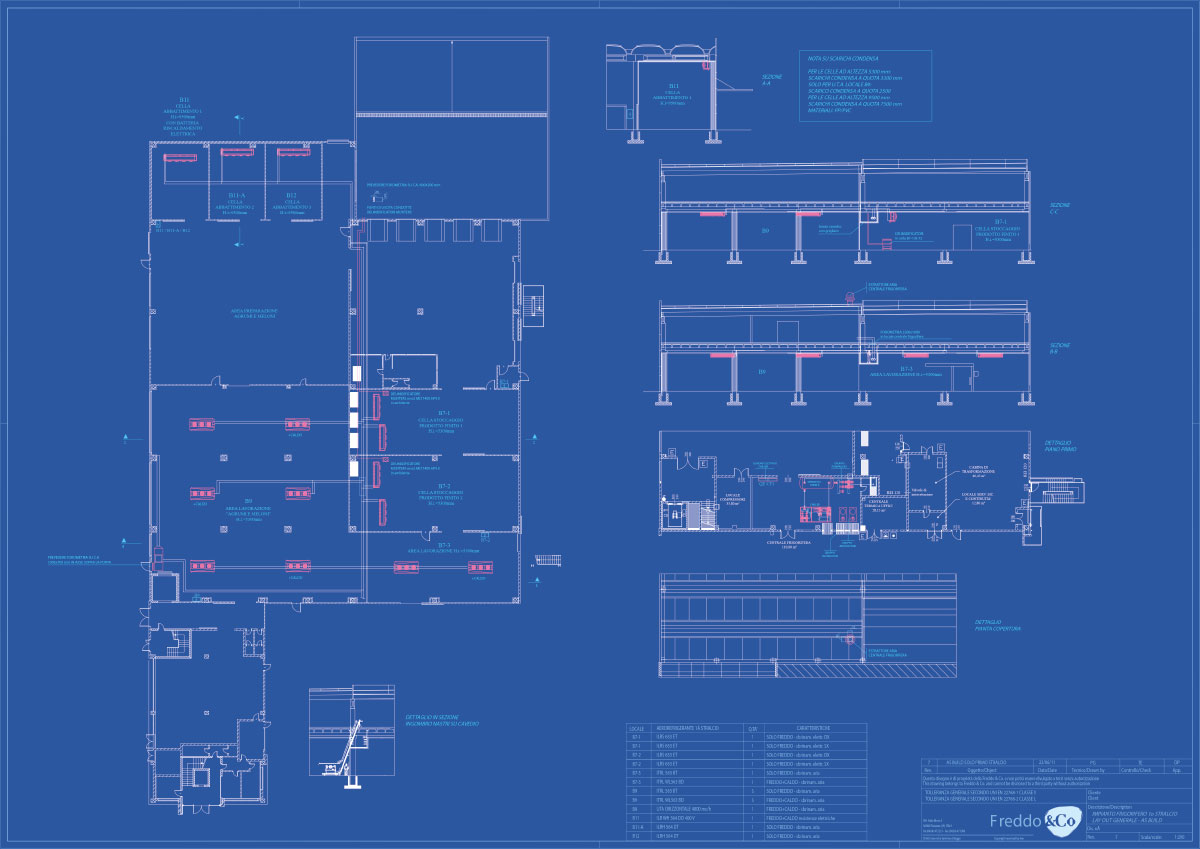

Our Technical Department consists of a large and well-structured team of expert engineers with years of experience that is available to assess our Customers’ needs and provide them with the best and most satisfactory solution.

Each system is tailored by Freddo&Co. to fit the Customer’s needs, so as to supply a finished product that is one of a kind, hi-tech, built-in and offering reliable cooling performance. This means offering, at the core, the best mechanical, electric, electronic and energy functionality, thanks to the first quality of the unit’s micro- and macro-components and to the expertise of the engineers that project and build it.

At our Headquarters in Pianezze (VI), we develop projects for orders that ship throughout Italy, Europe and the rest of the world.

But our list of satisfied customers also includes prestigious companies in other fields including:Automotive, Footwear, Plastics, Banking, etc.:

Practically speaking, wherever there is a need to ensure high performance at low temperature with the aim of generating energy savingsfor a host of industrial, technical and commercial processes, Freddo&Co. is sure to be there.

For each installation, we follow a strict sequential process:

Feasibility study:

Survey on site with collection, analysis and review of project data, working alongside the Customer

Structure Analysis:

Preparation of the draft project (sizing of refrigerating units, connecting pipelines, electrical boards and the electrical system; automation)

Cost analysis:

Quantification of costs and their optimisation, while maintaining unchanged the plant quality/performance ratio

Final project:

Project definition, with the involvement of all corporate departments (Project Management Office, Electronic Design, R&D, HSE, Purchasing, etc.)

Construction site coordination and executive works management:

Construction of the plant by our technical staff, which is in constant touch with our Management and with the other persons in charge (Client’s Project Management team); final set-up and commissioning.

Environmental responsibility

At Freddo&Co., we have always been aware of the environmental, social, economic and cultural impact that refrigeration processes have worldwide and, so, of life and of the future of all the human beings who inhabit it. These processes, in fact, absorb 10% of the world’s energy and account for 2.5% of greenhouse gas emissions (source: Frisbee EU Project Data).

This is why our Environmental Responsibility has always focused on two main aspects:

Energy saving thanks to our NewCold line

Energy saving thanks to our NewCold line Use of eco-friendly refrigerant gases

Use of eco-friendly refrigerant gases

When it comes to the second item, it now has been years that we have been encouraging everyone to Retrofit systems that still work with HCFCs (hydro-chlorofluorocarbons, which are responsible for eroding the ozone layer and for which the ban formally introduced by the Montreal Protocol, in force since 1989, has now been concluded).

Freon gas substitutes of HCFCs are HFCs (hydrofluorocarbons), which, like the first, are nevertheless responsible for the greenhouse effect and are the cause of global warming and of the resulting climatic upheavals (melting of glaciers, increase in desertification, increase of weather disturbances). Starting with the Kyoto Protocol (which was ratified in 2005), HFCs (also known as FGAS – fluorinated greenhouse gases) have likewise been included in the global divestment plan, which is currently implemented in Italy through Presidential Decree No. 43/12, and which entailed the obligation for Freddo&Co. to obtain national certification and to submit official declarations to an agency of the Italian Ministry of the Environment, and throughout Europe through EU Regulation No. 517/14, which introduced the GWP (Global Warming Potential) as the standard parameter for establishing the frequency of leak detection visits. The higher the GWP of an FGAS, the more it is responsible for the greenhouse effect and, consequently, the more the plant that contains it needs to be monitored.

The goal, which we fully endorse, is to encourage the use of refrigerant gases having a low GWP.

In these years, we have worked alongside institutional initiatives (conferences, workshops, European projects) but also in organising recreational activities (by sponsoring sporting events and cultural events in the territory) to engage the whole community in these environmental issues that we care for particularly, obtaining prestigious awards. We believe that we have done our duty and we intend to continue along this path.

To know how to adapt to the complex and constantly changing laws and the obligations they impose on businesses in our industry (such as the requirement to file plants registers and submit annual declarations to the competent agency, to install fixed leakage detection systems, etc.); to be updated on the latest generation of low-polluting gases; or to be involved in one of our many initiatives, please fill out the form below.

The passion that we have put into our work from the very beginning is the same passion for work we share with our Customers.

Certifications

To achieve this, Freddo&Co. reliability is ensured by the several certifications received from the Main Inspection and Audit Bodies:

with CE marking according to PED (Pressure Equipment Directive) 2014/68/EU.

Click here to view our Corporate Certificate or visit the FGAS National Online Platform.